Perseverance will be rewarded sooner or later … but,

mostly later.

Wilhelm Busch (1832 – 1908)

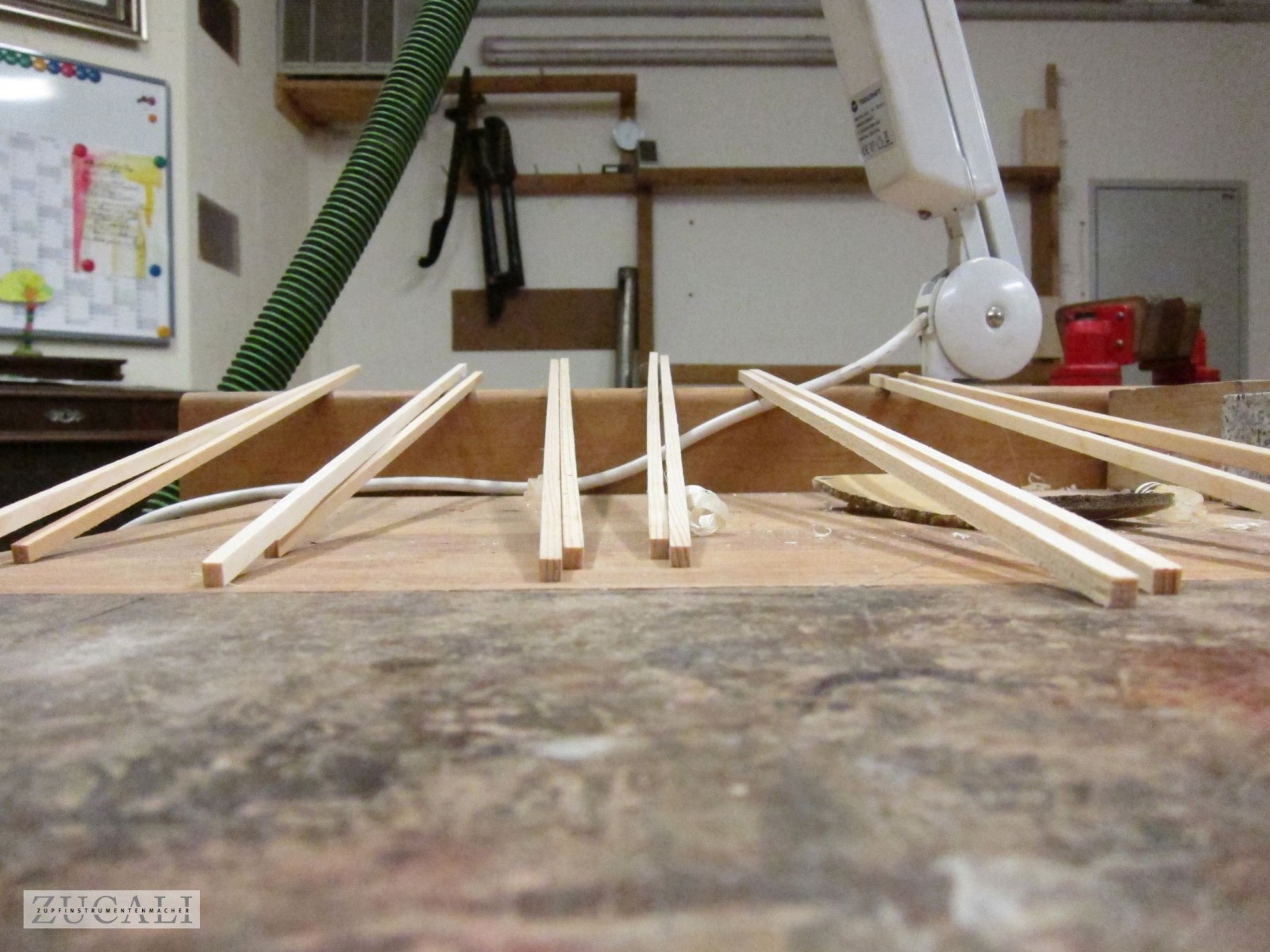

Building phase 2

… then I join all the parts together and suddenly it starts to look like a guitar. She’s not quite finished though. Many steps in the build are still to come.

The binding and pieces of purfling are inserted and fitted. Then the body is cleaned, and the fretboard prepped and glued on. After inserting the frets, the guitar is again sanded and cleaned thoroughly. After the bridge is finished, all the parts of the guitar which are not to receive lacquer are taped and the guitar is finally ready to receive her finish.

A good shellac polish takes about three weeks.

Once that step is done, I rework all the frets to give the guitar outstanding playability. Then the bridge is glued in place and the tuners are installed.

Last but not least, two final details are missing which have to be fitted with absolute perfection. These are the saddle and nut. Most of the time these are made of bone.

The last steps in manufacturing determine whether the guitar sounds great, or only good …